Raising the Bar in Asset Management: Kiwa’s Livestreamed, Cloud-Based Inspection Solution

Imagine a remote industrial tank installation in need of inspection. A pilot flies an inspection drone inside the tank. On two other continents, experts monitor the findings via livestream. The data are integrated with other relevant data at one central cloud-based location. There, specialised AI tools process the information, while other experienced experts can instantly access and share them. Kiwa’s cloud-based asset inspection platform is a market-leading platform that is changing the game in industrial inspection.

Drones are already widely used in industrial inspection. What sets Kiwa’s cloud-based asset inspection platform apart is its ability to integrate drone footage, real-time livestreaming, AI-powered image analysis, and centralized reporting into a single system, making inspections faster, safer, and more collaborative than ever before.

Viewing inspections in real time

Inspections are vital to ensuring operational safety, reliability, and efficiency at industrial sites such as tank farms, refineries, energy facilities, and infrastructure projects. Traditional inspections require on-site presence, multiple visits, collaboration between field teams and remote experts, and long reporting time. All of this makes them expensive, time-consuming, and sometimes risky.

‘With our cloud-based asset inspection platform’s livestreaming functionality, inspectors can share a live view of the inspection through an iPad or drone feeds,’ explains Jonas Van hove, Business Sector Leader Digital and Cyber Solutions at Kiwa. ‘Specialists can take part in the inspection in real time, offering guidance, reviewing critical points, and making decisions without being physically present. For example, if a Kiwa corrosion expert is based in Amsterdam, they can monitor an inspection taking place in Berlin without ever leaving the office.

Higher speed and quality, lower cost

The new approach saves 52% of time, accelerates decision-making, while maintaining safety and inspection quality. ‘This is particularly valuable when specialist knowledge is scarce or travel is difficult or costly, like in industrial environments or offshore inspections’ says Jonas. ‘Field inspectors get real-time input, and critical issues can be addressed immediately.’

He adds that on top of these benefits, Kiwa’s approach is saving customers a lot of money. ‘The cost reduction factor is a game-changer in the inspection field. The main way in which we reduce cost is by reducing operational downtime of the infrastructure. But there are many other expenses that we bypass. Think, for example, of the cost of scaffolding, renting elevating platforms, or the time and cost of having experts travel around the world to visit plants in-person. Those are all things of the past.’

Bringing inspection data together

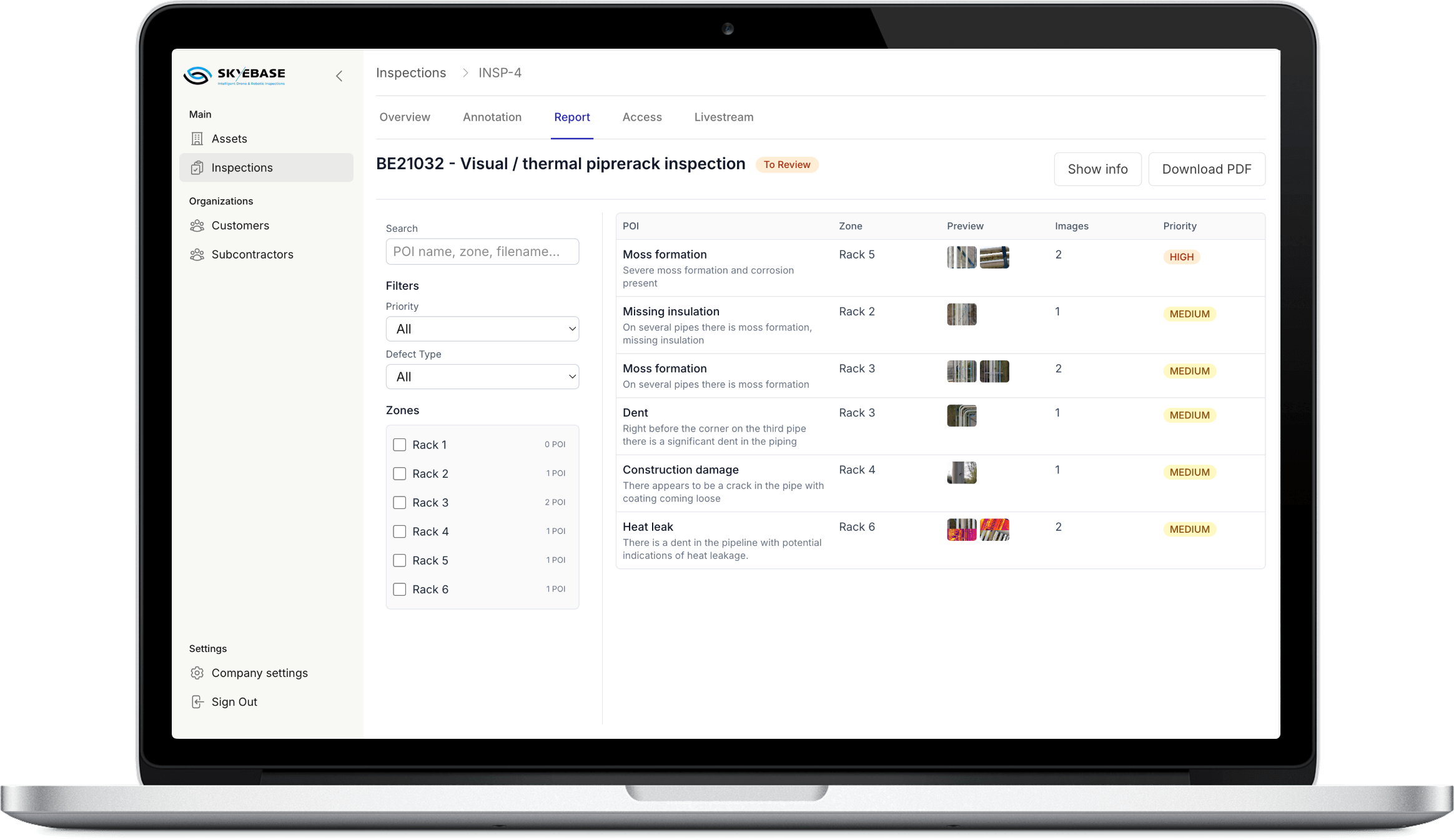

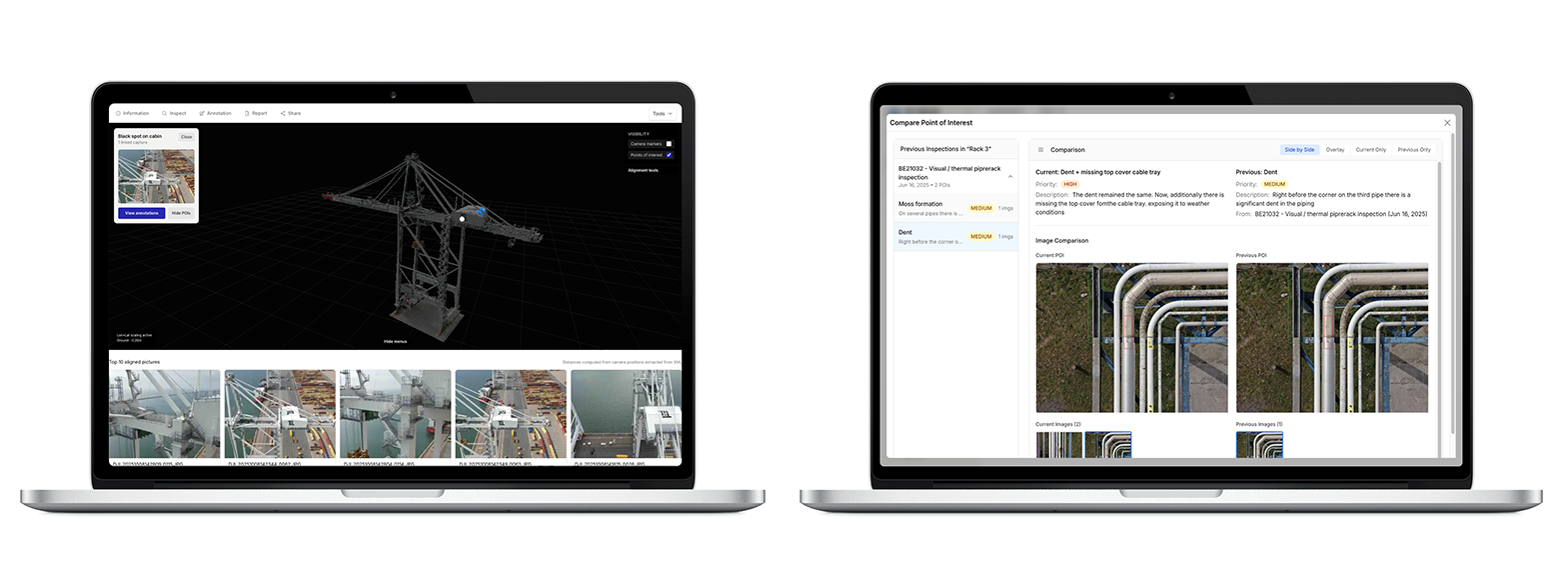

After the inspection, all data, documents, and images are stored in the cloud, organised by asset and location and visualized on a 3D model of the asset. By using a fixed structure and semi-automated drone routing, the platform ensures that every inspection is documented consistently, allowing teams to visualise, measure, and track asset conditions over time. Sharing data with stakeholders is simple, and remote collaboration is easy.

‘Centralizing inspection data not only makes reporting faster, but also allows for trend analysis and better long-term asset management,’ says Jonas ‘It’s a user-friendly way of communicating defects and follow-up actions to internal team members and subcontractors.’

AI-driven analysis and decision-making

Kiwa’s cloud-based asset inspection platform uses AI algorithms trained to identify cracks and defects in assets. The platform automatically annotates images and highlights areas of concern. Using AI for defect detection can make inspections up to twice as fast as traditional methods, while Kiwa’s 3D visualisation tools help teams review results together, virtually.

‘By combining AI and 3D visualisation, we make it easier for teams to see exactly where defects are, how the condition of their assets is evolving, and what needs to happen next,’ Jonas explains. ‘That can cut reporting time by up to 40 percent.’

Industrial tank inspections: a case study

To highlight the platform’s effectiveness, we asked Tom Daniëls, CEO and co-founder of SkyeBase, an intelligent drone & robotic inspections specialist and Kiwa partner, to expand on the example of a tank inspection.

‘For a visual inspection of the floor, walls, and roof of an industrial tank installation, an inspector, traditionally, would need to enter a 700 mm manhole,’ says Tom.

‘This alone poses a challenging and potentially hazardous situation, especially when internal scaffolding is not an option. By combining drone technology with our Cloud based asset inspection platform, a pilot can fly an Elios 3 drone into the confined space, while a remote Kiwa expert monitors the inspection via livestream. This improves safety, minimises operational downtime, and delivers powerful data through the Cloud based asset inspection platform’s digital reporting and 3D visualisation. In one case, the process saved nearly $40,000 USD in inspection costs.’

Similar cost and efficiency gains have been achieved across a range of inspections, from visual checks of flare stacks or silo complexes to wall thickness measurements of industrial tanks.

The benefits of Kiwa’s Cloud based asset inspection platform powered drone inspections

Real-time expert support: Remote specialists can guide in-person inspectors in real-time

Faster reporting: Data is shared instantly for quicker analysis and decision-making

Reduced risk and downtime: On-site visits and operational interruptions become less frequent

Improved accuracy: Expert knowledge is combined with AI-enhanced data processing

Long-term asset management: Defects and degradation can be tracked over time with consistent, GPS-aligned inspections or lidar.

The Kiwa difference

While drones provide access, the real value comes from intelligent software, data analysis, and collaboration with experienced experts. ‘At SkyeBase, we are masters in collecting and analysing data,’ Tom says about the partnership with Kiwa. Jonas adds, ‘Kiwa provides the experience in complex inspection work, the expert validation and the legal stamp. Together, we deliver a joint offering that combines innovative inspection technology with statutory certification and expert insights.’

Whether it’s a confined space, offshore structure, bridge, or energy facility, Kiwa’s partnership with SkyeBase ensures consistent, accurate, and high-quality reporting that supports proactive maintenance for long-term asset management. Concludes Jonas, ‘Our focus at Kiwa is on efficiency, structuring data, cutting cost, and reducing time from inspection to report. Our cloud-based asset inspection platform is not just a tool; it’s a platform that transforms how inspections are carried out and managed.’

Contact Us

Discover how Kiwa’s cloud-based asset inspection platform can support your asset management needs.