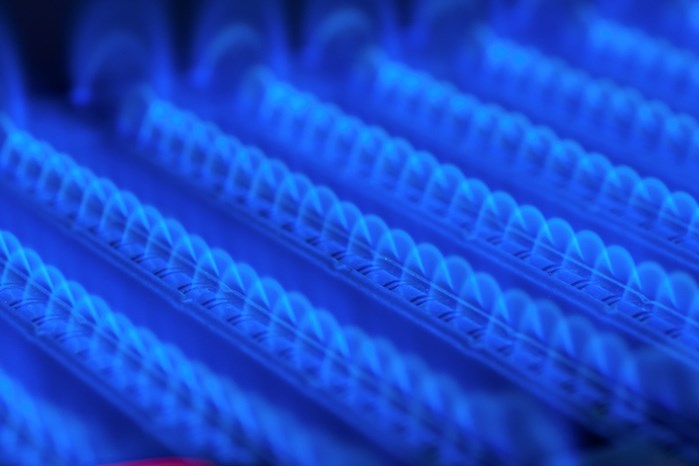

From gas to hydrogen: the hydrogen burner conversion, development and testing

Currently most of the burners are fed with natural gas. But what if this equipment will not run on gas in the future, but on hydrogen? With the energy transition underway that future is closer than you probably think!

The role and potential of hydrogen is acknowledged and stimulated more and more. Hydrogen roadmaps and funding emerge on national and international level and are now focusing on the complete supply chain instead of focusing on just one aspect of hydrogen. As a result of this movement we see that converting applications with gas to hydrogen is a hot topic. A clear example of this trend is the development of hydrogen burners and the accompanying retro-fitting of appliances. This can be burners that run entirely or partially on hydrogen. That is where Kiwa kicks in!

From gas to hydrogen

“When we look at hydrogen, we know it has different chemical and physical properties in comparison to natural gas, which makes the conversion of natural gas designed burners for hydrogen not so straight forward", say Jeroen Caanen and Edmund Fennema, hydrogen expert engineers at Kiwa. “For instance, the hydrogen flame could strike in the burner or the temperature of the burner could easily become too high affecting the burner materials and components causing safety issues or loss of efficiency. Also an alternative flame supervision principle is required for hydrogen burners. It is important to evaluate the effects of the new atmosphere on both the burners itself and on the combustion chamber or the impact that the combustion with hydrogen mixture has on the characteristics of the final product. However in recent studies we experienced these potential hiccups aren’t impossible to overcome and the possibilities that these burners offer to decarbonize the hard-to-abate sectors clearly came to the fore.”

Our experts continue: “Kiwa can help you to make sure these hydrogen applications meet the set safety and quality standards. We offer technical assistance to hydrogen burner manufactures already in the research and development phase of these products. We can support manufacturers either with existing burners and appliances (therefore assessing their ability to react to the different admixture of hydrogen and natural gas) or in the development of pure hydrogen specially developed ones.”

Hydrogen conversion, development and testing

Kiwa's state-of-the-art facilities and unique hydrogen expertise make it possible to test, assess and engineering assist retrofitted or newly designed device to be used with hydrogen. Together with our customers we discuss their wishes and requirements for developments in efficiency and effectiveness and come up with viable solutions, always keeping in mind quality and safety. In a joint effort we also execute testing programs for R&D departments and give recommendations on improvement.

Burner material compatibility assessment

Harald Ophoff, account manager at Kiwa, adds: “The development and functional testing of the hydrogen burner is one part, but equally important is the development and assessment of the auxiliary components that are used in combination with the burner such as sealings, flue gas systems, condensate drains, heat exchangers etc. Also, for these components the compatibility of the materials in combination with the hydrogen is often unknown. An independent third party assessing their hydrogen suitability as well as their optimal operating conditions, like temperature, pressure, mechanical load and presence of condensate or impurities etc., offers a great added value in their R&D and subsequent commercialization. In fact, such an assessment and corresponding recommendations will aid development and provide reliability and confidence to external parties and customers. We provide these material assessments."

How Kiwa can help

Our experienced engineers and test facilities can facilitate the development of hydrogen burners. As a partner for progress, we are here to help you and have the right capabilities to assess your metal and polymer products. Together we can make the energy transition work!

Would you like more information? Please contact us!