Why PAN and IAM testing matters

In their role as technical advisors, Kiwa PI Berlin, often works with project stakeholders to review the module manufacturer’s PAN files. PI Berlin’s analysis has revealed that, while conservative values are occasionally used, more frequently, manufacturer-provided PAN files contain aspirational assumptions for low light performance, temperature coefficients and/or IAM (Incidence Angle Modifier) curves.

Four recent examples of this specifically related to low light performance are detailed here, taken from different modules being considered for four different projects. In these cases, Kiwa PI Berlin was also shipped samples of the same modules to perform PAN measurements. The resultant measurement-based PAN files were compared to the manufacturer-supplied PAN files. To isolate the low light performance effects, all other PAN parameters were held constant between the two differently-sourced PAN files, which were then used in two PVsyst simulated sites. The site in Dublin, Ireland, has a higher frequency of low light conditions than the second site in Murcia, Spain, leading to more pronounced impacts of low light performance differences.

The results reveal that in all cases, the manufacturers’ low light performance assumptions were more aggressive than Kiwa PI Berlin’s measurements on the same modules, with deviations in specific energy yield ranging from 1.1% to 2.9%. While these differences might initially seem negligible, using these manufacturer-provided PAN files for utility-scale sites would lead to significant overvaluation in financial models, likely leading to underperforming assets that do not achieve their expected energy yield.

As part of Kiwa Solar’s Module Procurement Best Practices, third-party PAN testing is strongly recommended, both during module qualification, which is achieved via Kiwa PVEL’s PQP PAN testing, as well as during batch testing of modules being shipped to the project site, which is offered at all Kiwa Group labs.

Differences in Specific Energy Yield (kWh/kWp) between Kiwa PI Berlin measured-PAN files and manufacturer-provided PAN files for four different modules at two simulated sites.

Materials Assessed

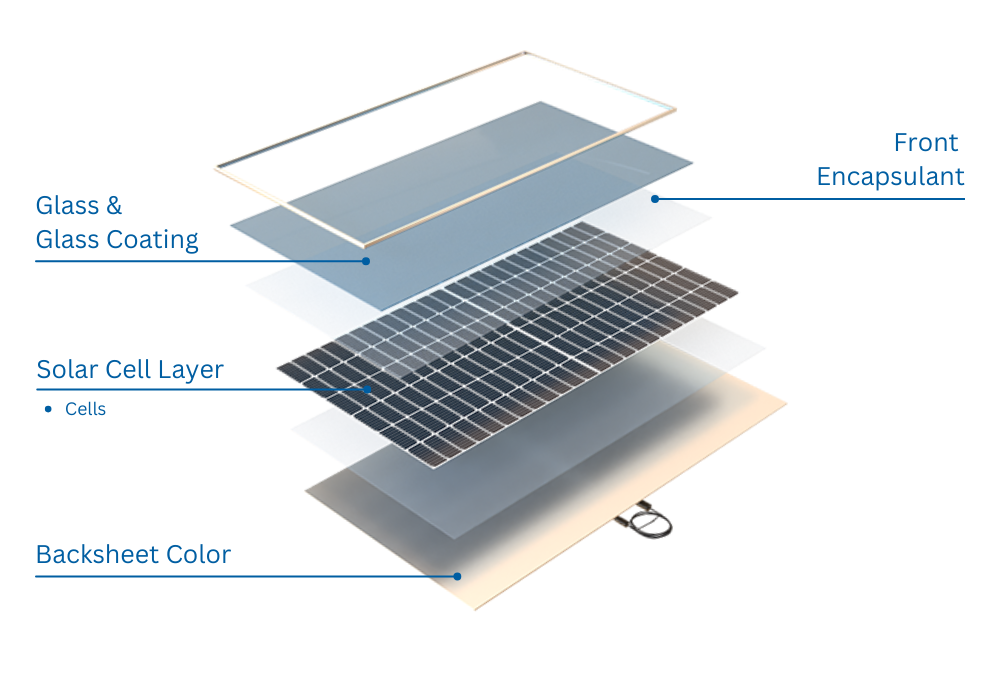

The cell has the greatest impact on PV module performance in the field, and certain cell technologies and designs (e.g., half–cut cell, heterojunction, thin film) can produce more or less energy in high temperature and/or low–light conditions. However, changes in the following components will impact PAN and/or IAM performance:

|

|

Test procedure

| For PAN testing, three modules are tested across a matrix of operating conditions per IEC 61853-1, ranging in irradiance from 100 W/m2 to 1,100 W/m2 and in temperature from 15°C to 75°C. Kiwa PVEL uses this flash data to modify PAN file parameters, resulting in a custom PAN file that has been optimized to reflect the in-lab measurements across all tested conditions. The accompanying report for each Kiwa PVEL PAN file includes all measured data and optimization outputs, as well as the module’s temperature coefficients as calculated from the flash test data. For bifacial modules, the Kiwa PVEL PAN reports include a “Bifaciality Factor,” or the ratio of the rear-side efficiency to the front-side efficiency, as well as other bifacial performance data. |

|

To illustrate the impact of the PAN files, each Kiwa PVEL PAN report includes simulations based on the PVEL-generated PAN file for two sites: a 1 MW site in a temperate climate at a 0° tilt in Boston, USA, and a 1 MW site in a desert climate at 20° tilt in Las Vegas, USA. The PAN reports also include single-axis tracker simulations for the same locations. The result of each of these simulations is a specific energy yield (kWh/kWp) value which can be used for benchmarking purposes.

For IAM testing, IEC 61853-2:2016 defines an indoor test method for characterization of the IAM values of a PV device with respect to the angle of incidence (AOI) by measuring short-circuit current (Isc). PVEL has improved upon this test method for characterization of the IAM profile for PV modules, including both glass//backsheet and glass//glass modules. PVEL’s indoor IAM testing method has shown superior results for precision and repeatability.

Note: PAN and IAM testing are optional when conducting a PQP.